Eye Wash Station Inspection Form

Eye Wash Station Inspection Form - Note that osha incorporated the ansi standard with respect to eye wash and shower station inspection. In addition, conduct an annual inspection to ensure compliance with standards for operation. Easily sign the printable eyewash station checklist with your finger. Ensure that the path to the eyewash/drench hose is not obstructed. Flush both eyes simultaneously (eyewash only); Activate the eyewash unit weekly to make sure it functions properly and can supply water. Weekly flush the eye wash and shower stations to ensure it is working. You can use an eyewash gauge to test the flow pattern. Web regularly test and inspect the eyewash station. Send filled & signed eye wash station inspection sheet pdf or save.

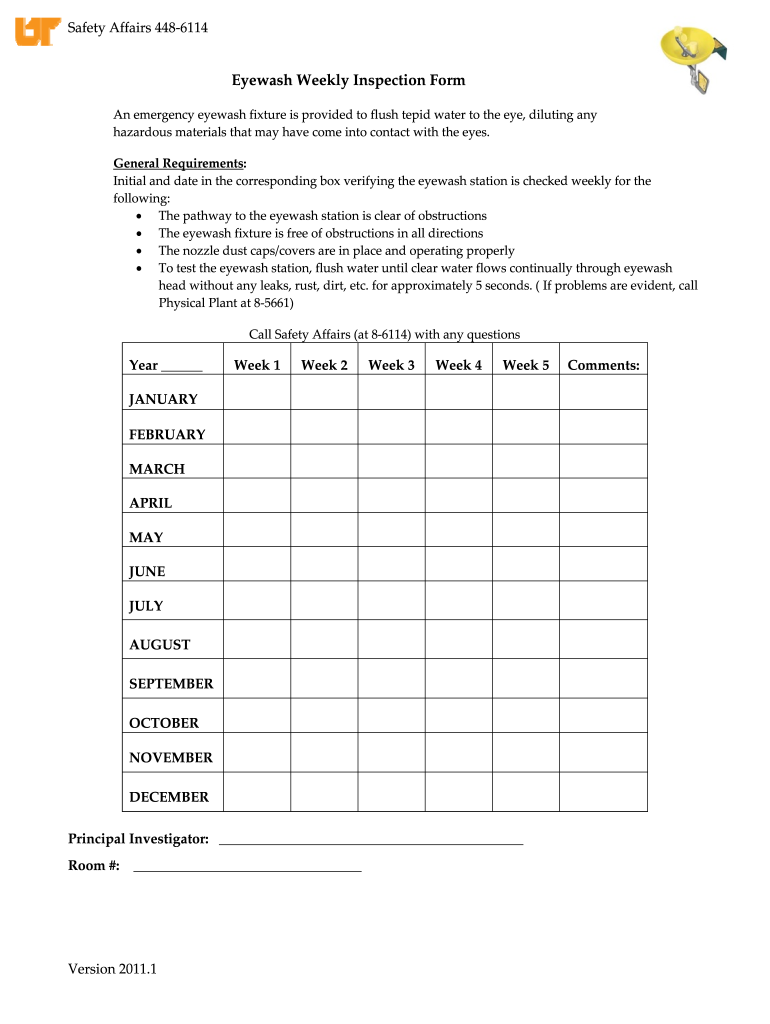

Activate the eyewash unit weekly to make sure it functions properly and can supply water. The water nozzle should be mounted between 33 and 45 inches above the floor and be at least six inches from any obstruction. Easily sign the printable eyewash station checklist with your finger. Web eyewash weekly inspection form. An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the eyes. In addition, conduct an annual inspection to ensure compliance with standards for operation. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. Initial and date in the corresponding box verifying the eyewash station is checked weekly for the You can use an eyewash gauge to test the flow pattern. Ensure that the path to the eyewash/drench hose is not obstructed.

Initial and date in the corresponding box verifying the eyewash station is checked weekly for the Provide freeze protection when possibility of freezing conditions exist; Ensure that the path to the eyewash/drench hose is not obstructed. Send filled & signed eye wash station inspection sheet pdf or save. Easily sign the printable eyewash station checklist with your finger. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. Web regularly test and inspect the eyewash station. The water nozzle should be mounted between 33 and 45 inches above the floor and be at least six inches from any obstruction. Activate the eyewash unit weekly to make sure it functions properly and can supply water. You can use an eyewash gauge to test the flow pattern.

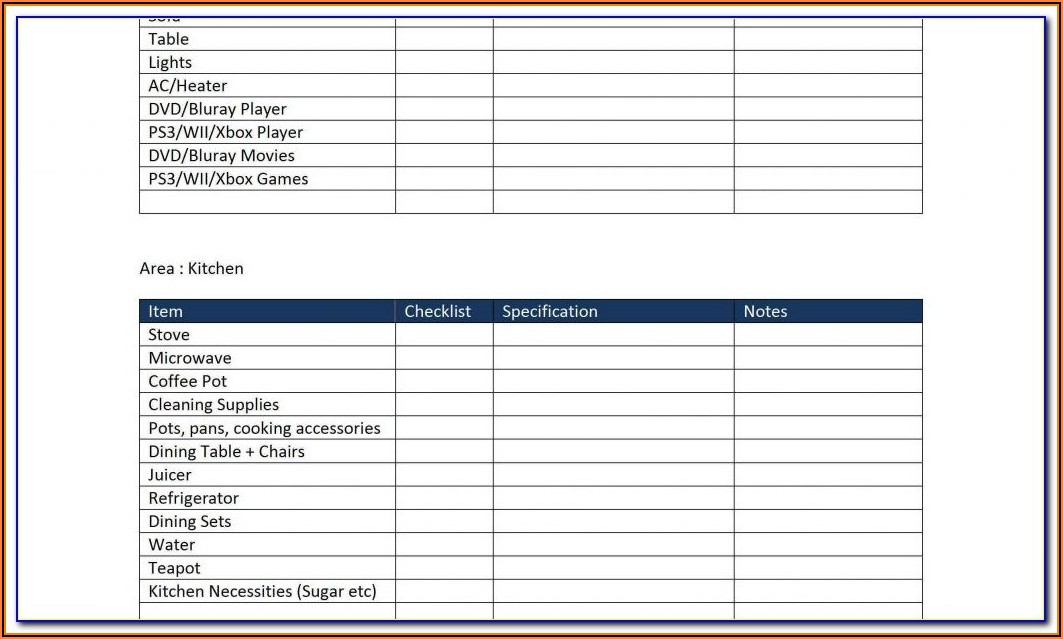

Eyewash Inspection Form Form Resume Examples Kw9k3dQ9JN

Provide freeze protection when possibility of freezing conditions exist; Weekly flush the eye wash and shower stations to ensure it is working. The water nozzle should be mounted between 33 and 45 inches above the floor and be at least six inches from any obstruction. Activate the eyewash unit weekly to make sure it functions properly and can supply water..

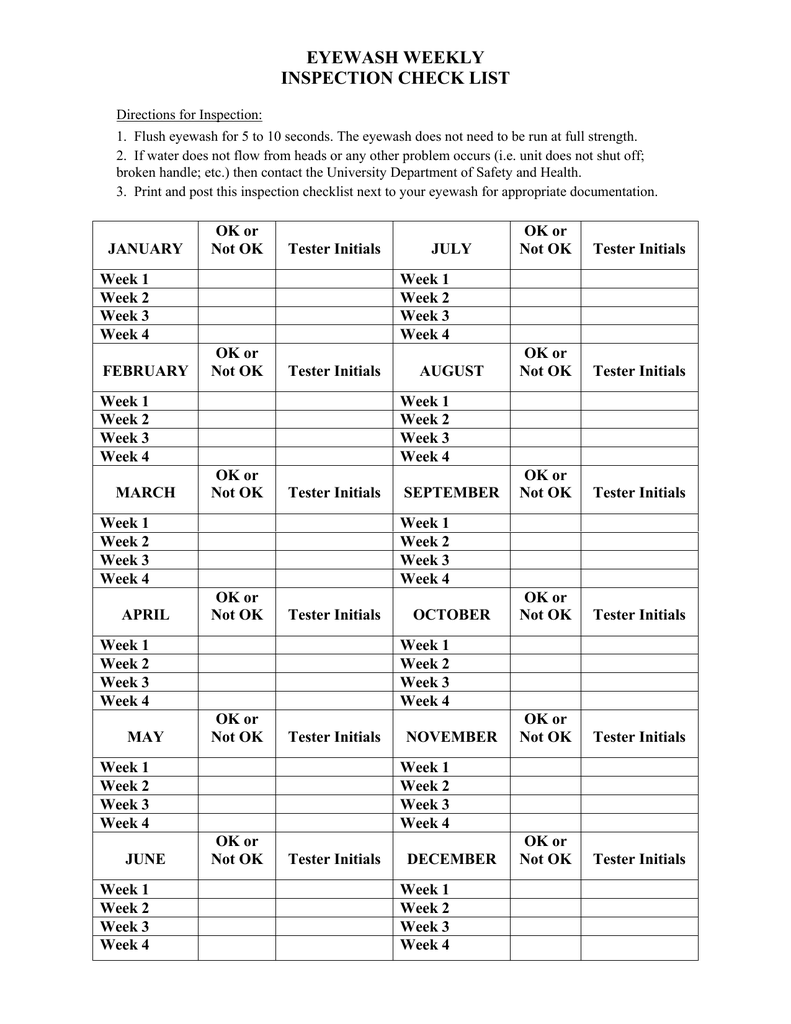

EYE WASH Weekly Inspection

Open the osha eye wash station inspection checklist and follow the instructions. An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the eyes. Easily sign the printable eyewash station checklist with your finger. Note that osha incorporated the ansi standard with respect to eye wash.

Eyewash Inspection Template Form Resume Examples ZL3nyJkKQ5

Web regularly test and inspect the eyewash station. Activate the eyewash unit weekly to make sure it functions properly and can supply water. Ensure that the path to the eyewash/drench hose is not obstructed. Send filled & signed eye wash station inspection sheet pdf or save. Provide freeze protection when possibility of freezing conditions exist;

Eye Wash Station Checklist +Spreadsheet Amazon Com Eye Wash Station

Open the osha eye wash station inspection checklist and follow the instructions. Flush both eyes simultaneously (eyewash only); Note that osha incorporated the ansi standard with respect to eye wash and shower station inspection. The water nozzle should be mounted between 33 and 45 inches above the floor and be at least six inches from any obstruction. Provide freeze protection.

Eyewash Log Sheet Editable Template Printable / 50 Printable Log Sheet

Open the osha eye wash station inspection checklist and follow the instructions. You can use an eyewash gauge to test the flow pattern. Send filled & signed eye wash station inspection sheet pdf or save. An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the.

Portable Eye Wash Station Inspection Form Form Resume Examples

Ensure that the path to the eyewash/drench hose is not obstructed. Note that osha incorporated the ansi standard with respect to eye wash and shower station inspection. Easily sign the printable eyewash station checklist with your finger. Weekly flush the eye wash and shower stations to ensure it is working. The water nozzle should be mounted between 33 and 45.

EYEWASH WEEKLY INSPECTION CHECK LIST

Activate the eyewash unit weekly to make sure it functions properly and can supply water. Open the osha eye wash station inspection checklist and follow the instructions. Weekly flush the eye wash and shower stations to ensure it is working. Easily sign the printable eyewash station checklist with your finger. Verify that nozzle caps are in place to prevent contamination.

Eyewash Log Sheet Template Printable / Excel Templates Eyewash Station

Open the osha eye wash station inspection checklist and follow the instructions. Ensure that the path to the eyewash/drench hose is not obstructed. Web regularly test and inspect the eyewash station. Flush both eyes simultaneously (eyewash only); Easily sign the printable eyewash station checklist with your finger.

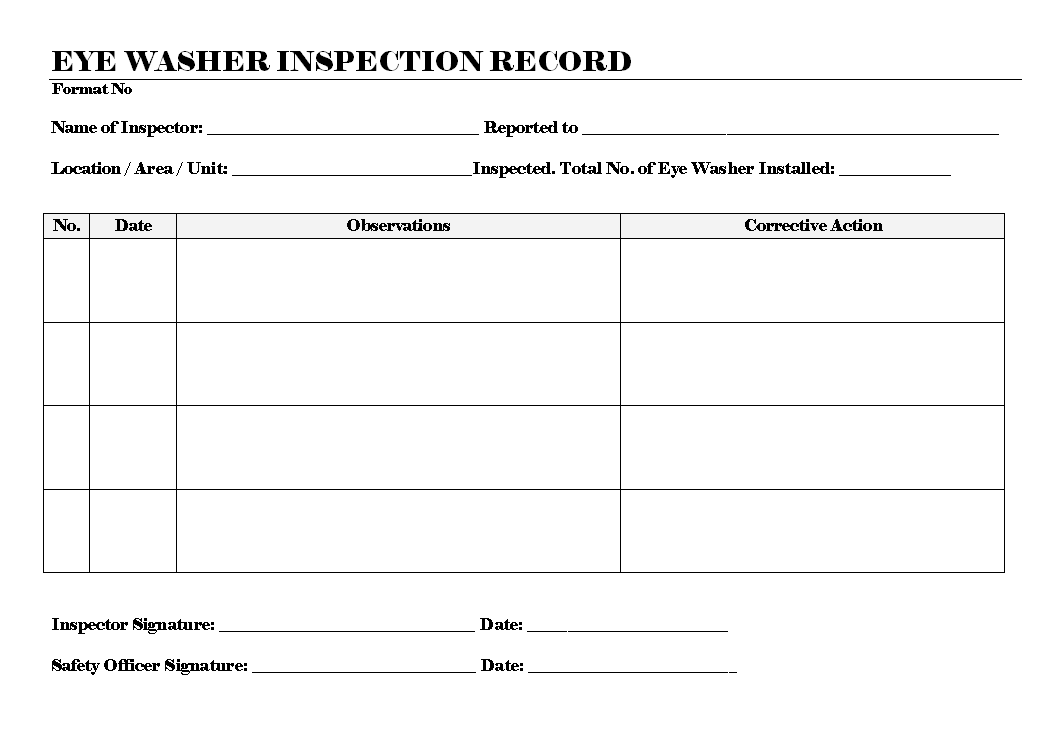

Emergency Eye Wash Station Inspection Checklist ScienceHUB

An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the eyes. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. Ensure that the path to the eyewash/drench hose is not obstructed. Web.

Eyewash Station Inspection Template Excel baldcirclespecialists

An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the eyes. Open the osha eye wash station inspection checklist and follow the instructions. Activate the eyewash unit weekly to make sure it functions properly and can supply water. In addition, conduct an annual inspection to.

Open The Osha Eye Wash Station Inspection Checklist And Follow The Instructions.

Provide freeze protection when possibility of freezing conditions exist; In addition, conduct an annual inspection to ensure compliance with standards for operation. You can use an eyewash gauge to test the flow pattern. Easily sign the printable eyewash station checklist with your finger.

Web Eyewash Weekly Inspection Form.

Note that osha incorporated the ansi standard with respect to eye wash and shower station inspection. Weekly flush the eye wash and shower stations to ensure it is working. Ensure that the path to the eyewash/drench hose is not obstructed. Activate the eyewash unit weekly to make sure it functions properly and can supply water.

An Emergency Eyewash Fixture Is Provided To Flush Tepid Water To The Eye, Diluting Any Hazardous Materials That May Have Come Into Contact With The Eyes.

Flush both eyes simultaneously (eyewash only); Send filled & signed eye wash station inspection sheet pdf or save. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. The water nozzle should be mounted between 33 and 45 inches above the floor and be at least six inches from any obstruction.

Initial And Date In The Corresponding Box Verifying The Eyewash Station Is Checked Weekly For The

Web regularly test and inspect the eyewash station.